Water advancing from both ends of a bay in a ‘siphonless with tailwater backup’ irrigation system.

BANKLESS irrigation systems that water fields from both ends by employing head-ditch inflow and tailwater backup are creating greater water use efficiencies and achieving higher, more uniform crop yields than conventional siphon-fed systems.

Also known as siphonless irrigation, bankless systems are becoming more widely adopted throughout Australian irrigation regions as farmers seek ways to cut costs and make every drop of water count.

Based at St George in southern Queensland, irrigation specialist, Glenn Lyons, has been designing bankless irrigation systems for farmers throughout the irrigation industry, from cotton growers in Central Queensland to maize growers in Victoria.

“Generally, farmers are converting to the new system when the field is due for a re-grade. They shift a little more dirt to create the new configuration, and then install the concrete structures,” he said.

“It costs something like $1500/hectare. For someone to do a normal regrade and reform beds, they spend about $500/ha. So, it is probably an extra $1000/ha for the conversion.”

A fully watered bay in a bankless irrigation system.

Mr Lyons said the capacity to save water and more evenly water the crop in bankless systems achieved higher gross margin returns, which meant the conversion could be paid off in a relatively short time.

He said his clients who had switched from traditional siphon irrigation to ‘siphonless with tailwater backup’ systems were consistently achieving 25 per cent water saving on pre-waterings and 10pc on in-crop waterings for an overall water saving of 15pc over siphons.

“One client recently pre-watered 150 hectares with not enough tailwater to start his pump,” he said.

“There is also a yield premium because you are not waterlogging the crop, and are getting better infiltration down the tail drain end. Generally with siphon systems, the paddock ‘rolls over’ in the last 30 to 50 metres from the tail drain and the water gets a scoot along. It is hard to get the last 50 metres to water properly.

“But if you back up the tailwater, instead of the bottom 100 metres of the paddock being the worst yielding part, it is now the best yielding part of the paddock.

“There is a fixed growing cost of about $4000/ha – so every per cent you can improve in terms of water efficiency or yield doesn’t just improve the profit margin by 1pc, it might improve it by 4pc. If there is a 5pc improvement in yield it might mean a 20pc improvement in profit. Combining a 5pc yield gain with a 10pc water efficiency gain could double your profit.”

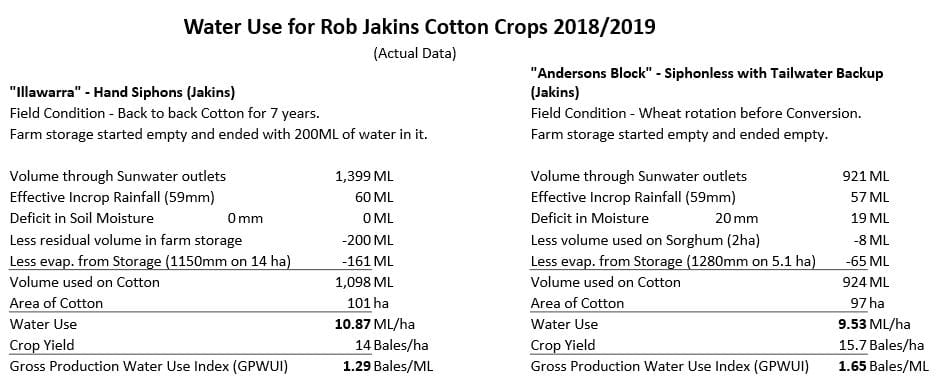

Figure 1: Comparison of water use and production between Rob Jakins’ siphon-irrigated ‘Illawarra’ block and his ‘siphonless with tailwater backup ‘Andersons block’ at St George.

……………………….

How does ‘siphonless irrigation with tailwater backup’ work?

To convert a field to siphonless irrigation, the rotobuck area is excavated to create a water distribution basin, and the first 30 metres into the field is graded uphill before going downhill. The last 150m of the furrow is made flatter.

The field is divided into bays with check banks that run from the head ditch through to the taildrain. A check structure is placed across the taildrain on the check bank alignment to hold the tailwater in the section.

To initiate the irrigation, water fills the distribution basin in the first bay then pushes out into the furrows. The water flows up the short (30m) reverse grade to a sill to help even distribution, then flows down the furrows to the taildrain. At the bottom end of the field, the gates in the taildrain are closed, forcing the tail water to back up the field.

When the water coming down meets the water backing up, the head ditch gate into Bay 1 is closed and the one to Bay 2 is opened. Water then flows into Bay 2’s distribution basin, rises into the furrows and runs down the field.

An hour or so after the head ditch water is changed, the check structure in the tail drain is lowered to allow the tailwater from Bay 1 to flow across to Bay 2. The check structure is then raised so that as the new water coming down Bay 2 joins, the tailwater will back up in Bay 2 only.

The re-use of tailwater process is repeated for further bays.

Water advancing down the rows from the head ditch.

A tailwater drain filled and backing up the rows.

Tailwater being released into the next bay.

Grain Central: Get our free daily cropping news straight to your inbox – Click here

HAVE YOUR SAY