RESEARCH in Western Australia is finding deep ripping to a depth of between 50 and 70 centimetres can lift wheat, canola and lupin yields by helping to alleviate subsoil compaction.

The Department of Agriculture and Food WA’s trial deep ripper working in grey clay soil in Ongerup. Photo: DAFWA.

But timing this strategic tillage operation can be problematic.

Optimal results on a range of deep sands, sandy loam, duplex and some clay soils typically occur when ripping is carried out just after opening rains in autumn.

At that time, soil is moist enough to allow penetration of the deep ripping tynes, but not too wet to cause ‘smearing’ without shattering the compacted layers.

Earlier deep ripping, in February or March (before peak demand for labour and machinery at seeding), can be more convenient – but means operating in dry soil.

GRDC-funded research by the Department of Agriculture and Food WA (DAFWA) is investigating the effectiveness of early deep ripping on dry soils and subsequent crop performance.

Soil compaction in WA – the issue

It is estimated the average opportunity cost of lost agricultural production due to soil compaction in this State is upwards of $800 million per year (based on DAFWA modelling data).

Compaction can result in:

- Reduced soil biological activity

- Increased soil strength

- Poor soil structure

- Stunted crop root growth

The use of increasingly heavy cropping equipment is exacerbating the problem of deep subsoil compaction. Particularly affected are sandy soils that also have a relatively low water holding capacity.

Deep ripping has been demonstrated to break-up compacted soil and is particularly effective when used in controlled traffic farming (CTF) systems.

Timing options for deep ripping

Subsoils are harder when they are drier, so more horsepower is required for deep ripping and this can increase costs.

DAFWA estimates costs can range from $50-60 per hectare for standard ripping, to a depth of 30-40cm, up to $70-90/ha for ripping to a depth of 50-70cm (depending on machinery and soil conditions).

On water repellent soils, research and experience in WA have found that ripping dry soil can result in greater expression of the water repellence and poorer establishment.

Aside from deep ripping in dry soil early in the year, other opportunities that might arise to carry this out while avoiding competition for resources at seeding include:

- After out-of-season rainfall

- In a fallow year

- Up to three days after seeding (early enough not to disturb establishing plants)

- During the growing season in the inter-row of crops sown on wide rows.

DAFWA’s rule-of-thumb for determining if soil is too wet for deep ripping is the ability to roll a ‘sausage’ (or thread) – with a three millimetre diameter – of hand-moulded subsoil in the palm of your hands.

Ripping in these conditions, especially on some loamy yellow sands, may leave slots behind the ripper tyne – as the wet subsoil flows around it.

In soils with a high clay content, deep ripping in wet conditions can smear the edges of the ripping line, causing problems for root exploration and plant growth and higher wear on equipment such as the topsoil slotting plates.

Trials of early deep ripping in dry soil

Retired DAFWA senior research officer, Dr Paul Blackwell, said recent research and experience in WA had shown deep ripping in dry soil before seeding could be successful in improving soil break-out patterns, breaking-up compacted subsoil layers and lifting crop production.

He said this process required strong machinery with good traction and could be further improved with the use of shallow leading tynes in front of the ripper tynes.

Trials at a Liebe Group site in Buntine in 2013, 2014 and 2015 found that using a shallow leading tyne design, with tynes at a depth of 10cm working in-line and ahead of the deep ripping tynes at 30-50cm, reduced draft force by up to 18 percent on clay-textured soil.

On sandy-textured soil, with the leading tynes working at a depth of 10cm in front of the deep ripping tynes at 30-50cm, the draft force was reduced by 10 percent.

Dr Blackwell said this would lead to significant fuel and time savings.

He said in 2013, the use of the shallow leading tynes produced a wheat yield response of about 0.5 tonnes/ha when ripping to a depth of 30cm on an acid yellow sand and this increased to 0.9t/ha when ripping to a depth of 50cm (compared to a control with no deep ripping).

At a wheat price of $280/t and ripping cost of $50-75/ha, his analysis found the profits from deep ripping were upwards of $200/ha in that season.

Dr Blackwell said incorporating lime with deep ripping, followed by a high nitrogen (N) fertiliser rate at seeding, had potential to further improve crop yields and returns.

He said a key to success of the shallow leading tyne system was using a weighted, or pressurised, cage roller behind the ripper to break up any clods and create an even seed bed.

His trials have also indicated there may be significant soil flow benefits in using topsoil slotting plates when ripping in dry topsoil conditions.

Dr Blackwell said further research was needed to determine the optimum plate shape for soil flow and reduced draft.

Value-adding with CTF

Ripped soil can be very soft and more susceptible to re-compaction that can cause trafficking issues at seeding or spraying.

To maximise the benefits of soil renovation from deep ripping and minimise risks of re-compaction, adopting a CTF system is recommended.

Firm pathways can be established by either lifting ripper tynes or using shallower ripper tynes in line with the wheeltracks.

Research and grower experience indicates this can also save about 10-15 per cent in fuel costs by not ripping up the whole paddock.

Leaving deep ripped soil to settle for about two weeks can help to reduce seeding challenges.

DAFWA development officer, Bindi Isbister, said there were some trafficking issues in 2016 WA crops where soils had been deep ripped early in the year, even in a CTF system where wheeltracks were not ripped.

She saw cases where seeding equipment sank in soft sand and in areas where the soil surface had lifted and the main wheeltracks for the seeder and sprayer were lower – making seeding depth control difficult.

Ms Isbister said at Esperance a sprayer fell off the wheeltracks and equipment tended to get bogged at faster speeds.

To overcome these problems, she said growers could:

- Use good ground-following seeder design

- Drop the tyre pressure in the bar wheels to improve flotations

- Slow down the sprayer

- Create a shallow ripping tyne in the wheeltrack – forming a rut for the sprayer to ‘track’ in.

Ms Isbister said if ripping deeper than about 55cm and soil conditions were dry, it might be advisable to narrow the ripping widths to about half or one third of the seeder width (typically 4.5-6 metres) to help tynes dig deeper within the tractor capacity.

Crop responses to deep ripping in WA

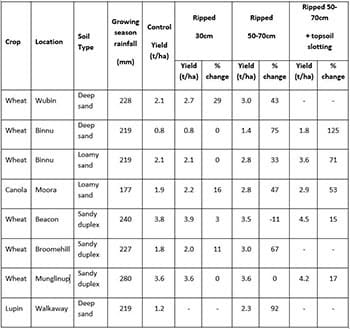

Crop yield results from recent DAFWA deep (50-70cm) and shallow (30cm) ripping trials conducted at a range of locations across the WA grainbelt are summarised in Table 1, compiled by DAFWA research officer Dr Stephen Davies.

The data indicate that, in sandy soils, yield gains of up to 75, 47 and 92pc are possible in wheat, canola and lupin crops, respectively, after ripping to a depth of 50-70cm (compared to the control with no deep ripping).

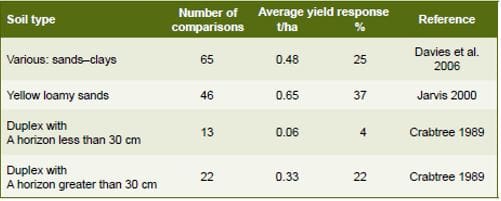

Ms Isbister said research and experience in WA conditions showed responses to deep ripping were typically less in heavier soil types.

She said as ripping increased plant root growth, access to nutrients and water down the soil profile, deep ripping responses would vary according to rainfall and seasonal conditions.

This has been particularly evident in lower rainfall areas (less than 350mm) of the eastern grainbelt.

Deep ripping can also induce a penalty in some seasons that have a very dry finish (such as 2016) or where there are other soil constraints.

Table 1: Summary of crop yield (in tonnes per hectare) and percent change in yield (from control) from some DAFWA deep ripping trials carried out in WA in recent years. Source: DAFWA.

Historically in WA, it has been common for growers to deep rip prior to the wheat phase of the rotation.

Dr Davies said this might have been due to using deep ripping to chase N in the 1980s and 1990s, rather than soil moisture that was now a key motivation to remove the compaction layer.

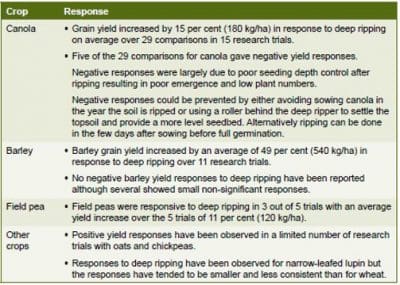

But, he said research and experience had since shown there were potential yield benefits from deep ripping before canola, lupins and barley, as shown in Tables 2 and 3.

Lupins following deep ripping

Lupin yield responses to conventional ripping, to a depth of 30cm, have been observed for narrow leafed lupins in some WA trials. But this response tends to be lower than that for wheat.

A 2015 grower trial at Walkway on a pale white sand showed an average 1.1t/ha increase in lupin yields after ripping to 70cm.

A yellow sand at the same farm produced a 0.1-0.15t/ha response.

Ms Isbister said this grower reported the lupins sown on deep ripped areas that year were significantly easier to harvest than those on other areas, due to the crop being taller.

Nitrogen and deep ripping

Crop yield responses to deep ripping are typically highest in the first year of the treatment, mainly due to improved plant root access to and efficient uptake of stored soil moisture and nutrients (especially N).

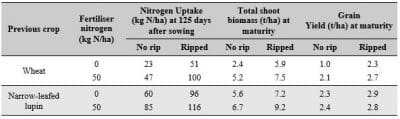

Past trial results from Bill Bowden, formerly of DAFWA, have shown deep ripping can improve N uptake, crop biomass and grain yield.

As highlighted in Table 4, his research found uptake of both fertiliser and residual N from a previous lupin crop was improved by deep ripping.

Addition of fertiliser N improved crop biomass, but in this trial grain yield was only increased when the preceding crop was wheat (not when it was lupins). This also demonstrates how more biomass does not always translate into higher yields, as water becomes limiting at the end of the season.

Table 4: Example of the impact of deep ripping on nitrogen uptake, total shoot biomass and grain yield of wheat grown in loamy sand at Wongan Hills following a wheat (1.9 t/ha) or narrow-leafed lupin crop (1.1 t/ha). (Data provided by Bill Bowden, DAFWA)

Source: DAFWA

HAVE YOUR SAY