Ask a WeedSmart Expert

THE pressure for growers to get across a large area in a short period of time has led to an increased use of complex tank mixes – but the efficiency gains of this practice can easily come unstuck if taking short-cuts results in not being able to spray the brew out.

FMC technical services specialist, Stephen Pettenon, says if there are many products in a tank mix, it becomes increasingly difficult to prevent adverse chemical reactions from occurring in the ‘brew’.

Stephen Pettenon

“If operators follow a few guiding principles it is possible to safely mix a complex combination of herbicides, insecticides and even crop nutrients,” he says. “But it is also quite easy to end up with a tank of sludge that cannot be sprayed out, if you don’t take the time to get it right.”

With several new products, such as FMC’s Overwatch, Syngenta’s Reflex and Callisto and Bayer’s Sakura Flow, being released as suspension concentrates (SC), it is important to recognise that there is no guarantee that a desired combination can be mixed and sprayed out effectively.

“The first consideration is whether the tank mix is safe and if there are any biological antagonisms likely to arise,” Mr Pettenon said.

“This is where one product impairs the efficacy of a tank mix partner or increases the risk of crop damage. These antagonisms are relatively rare in pre-emergent situations, but where they occur they can also have implications for the evolution of herbicide resistance.

“The second, and more common, problem in tank mixes is the potential for the mix partners to be chemically incompatible. This can result in the formation of irreversible precipitate reactions or some components settling out of suspension and potentially causing blockages.”

Tank mixing involves many products and so potential crop safety losses must also be a consideration.

The WeedSmart Big 6 tactics for reducing the impact of herbicide resistant weeds on farming systems also promotes the importance of applying herbicides in the most effective and safe manner.

*Always read the label and check with your agronomist for compatibility before mixing and applying agricultural chemicals.

If transfer systems are used it is important that the small tank contains only one of the spray mix components.

What are the top tips for complex mixes?

In brief: The number one tip is to take your time. Rushing is the most common cause of tank mix failures.

The details: Products that are SC or water dispersable granules (WDG) need time to properly disperse. They also need sufficient solvent – that is water. Start by filling the tank to at least 70 per cent of its capacity with good quality water before adding any products. Each chemical must be added and dispersed fully before the next chemical is introduced to the tank. Keep water rates above 80 L/ha and ensure the agitation system is working well to improve the likelihood of keeping a complex mix in suspension.

Simplify the mix if you can. Keeping two or three products in a compatible mix is generally less challenging than achieving the same for a six or seven-way mix. Be realistic about what can be achieved in a single tank mix.

Do I need to be careful when choosing between formulations?

In brief: Yes, not all products are created equal.

The details: Some products are only available as a powder formulation (solid concentrate – SC) and it is not possible for them to be produced as a more soluble, emulsifiable concentrate (EC).

For example, Rustler 900 WG is a formulation that requires plenty of time to absorb water and swell the granules and then to disperse into the tank water. Allow at least 5 to 10 minutes, with agitation, before adding the next product. Suspension concentrates also require significant amounts of time.

Some formulations of the same active can behave vastly differently in tank mixes. A well-known example is that potassium (K salt) loaded glyphosates are often less compatible in a tank mix than isopropylamine (IPA) and monoethanolamine (MEA) loaded glyphosate products.

K salt formulations have never been good mixers because the potassium ion has a high ionic charge and small molecular mass, so it has a high affinity to bind with other molecules.

K salt formulations are known to cause flocculation issues if mixed with SC and WDG products and such combinations should be avoided. There are some brands of potassium glyphosate formulations with complex surfactant systems that are mixing-friendly, provided agitation is maintained.

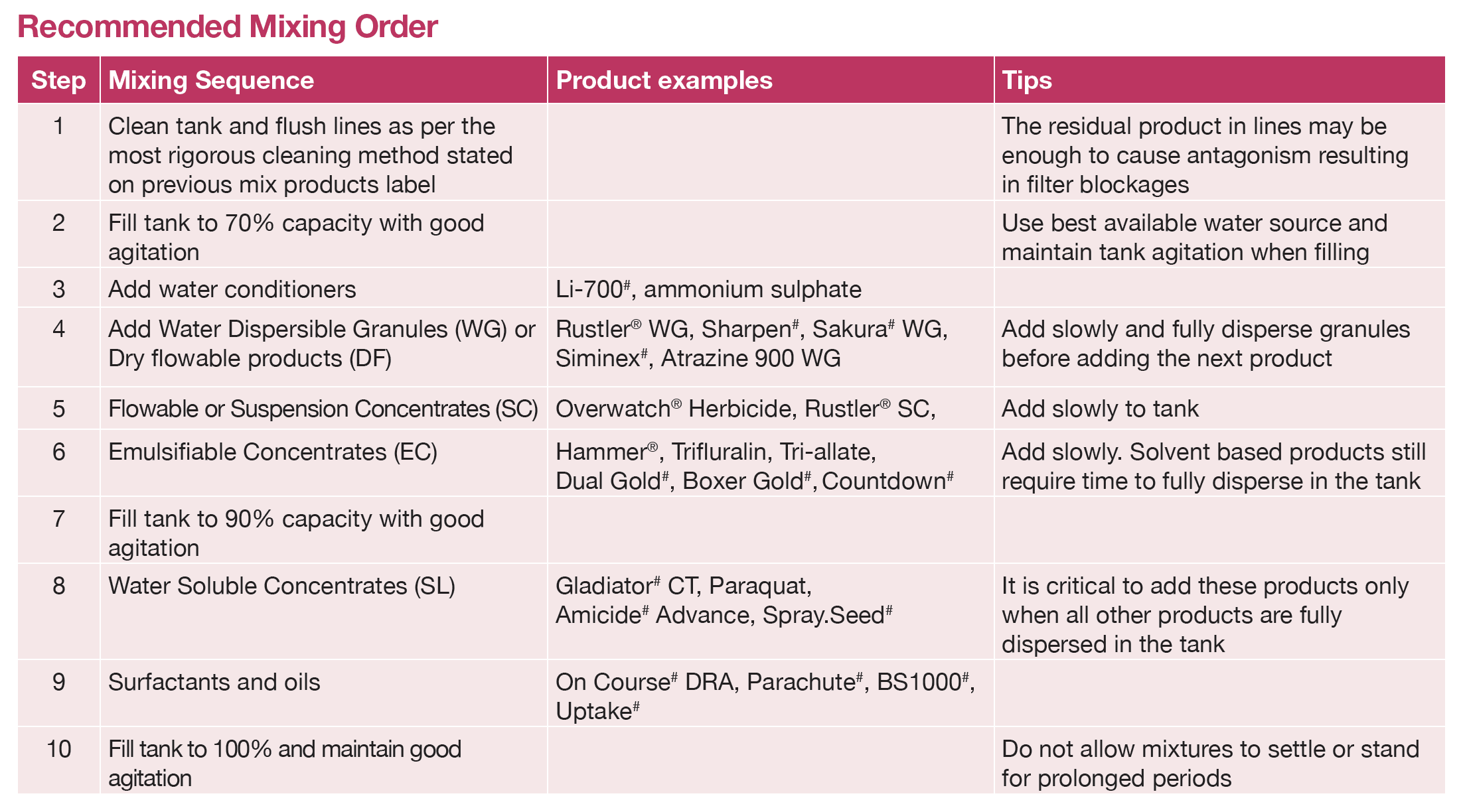

Mixing order is crucial. Start with correctly conditioned water and then add the least soluble formulation first, allowing time for each product to disperse before adding the next component.

If you are unsure of the compatibility of the desired products for the mix, conduct a jar test or ask for technical advice. The major chemical companies are involved in ongoing compatibility testing of the products that may be useful tank mix partners.

Recommended mixing order. (Source: FMC)

Are there things I can do with the sprayer set up to minimise potential problems?

In brief: Avoid over-filtering and be careful when using transfer systems.

The details: It is common for spray rigs to use filtration that is too fine for the nozzle size being used. Using the correct in-line and secondary filter for the selected nozzle can greatly reduce the chance of blockages.

For example, the standard 100 mesh filters on most spray rigs may not be the best choice for handling the mix. If using a single orifice nozzle that is 02 or greater in size, then using a 100 mesh filter (when a 50 mesh is adequate), will greatly reduce the area of passage and potentially increase the chance of blockages.

Pre-mixing some or all the products in a transfer system or nursery tank can have some advantages in time efficiency for refilling the sprayer. Problems can arise if the full mixture of chemical is added to a small nurse tank. For example, if the full load of components is added to a 1000-litre nurse tank destined for a 5000-litre spray rig re-fill, there is unlikely to be sufficient water in the nurse tank to allow for complete dispersion of the product. If transfer systems are used it is important that the small tank contains only one of the spray mix components.

Source: WeedSmart

How to ask a WeedSmart question

Ask your questions about about tank mixing herbicides and other agricultural chemicals on the WeedSmart Innovations Facebook page WeedSmartAU, Twitter @WeedSmartAU or the WeedSmart website www.weedsmart.org.au/category/ask-an-expert/

WeedSmart is the industry voice delivering science-backed weed control solutions to enhance on-farm practices and promote the long term, sustainable use of herbicides in Australian agriculture.

HAVE YOUR SAY