THE ad in the paper that reads “Horse, free to a good home” seems to be a good deal at first, but what is the true cost of owning a horse? Roughly similar to running a Lamborghini as I understand!

The do it yourself narrow windrow burning chute seems cheap at the time, but what is the true cost?

It depends!

It depends on crop type, yield, area, number of harvesters etc.

Over the years we at AHRI have communicated the costs of harvest weed seed control (HWSC) using our best estimates. We have used average yield and crop area and we limited the estimate to cereal crops. In this AHRI insight we go one better. We have developed an interactive model that allows you to input your details and give the best cost estimate for you.

What it shows is that while there are significant differences in up front capital cost for the range of HWSC tools, the cost per hectare can be very similar for all tools when all of the factors, including nutrients, are considered.

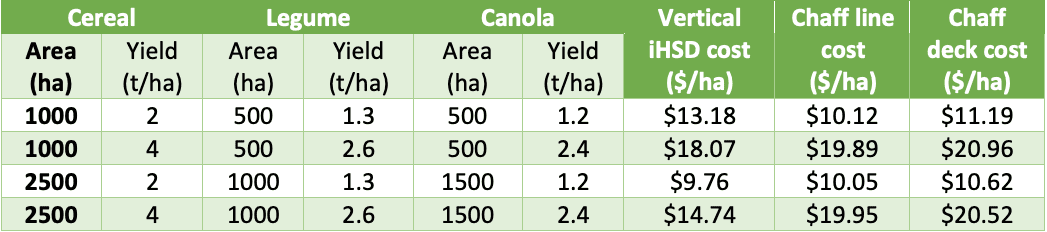

Table 1 below is data from our new Estimated Cost of HWSC model. This data represents farms of different sizes and yield, all harvested with one harvester. It assumes a 10 per cent reduction in harvest capacity when using a seed impact mill and a slower harvest speed was used for higher yielding crops.

To find out how much HWSC costs you, access our free downloadable model and some explanatory notes about it, click below.

CLICK HERE FOR MODEL

All models are wrong, but some are useful!

It is very difficult for this cost of HWSC model to be precise, and we consider it to be accurate within the cost estimates that we have. As we gather more accurate cost estimates in the future we will update this model.

Below are some notes that describe the key assumptions that we have used for the model.

Nutrients

One of the most important and sometimes overlooked costs of HWSC is the value of the nutrients contained within the residue that is removed.

In 2011, Peter Newman (then DAFWA research officer) measured the amount of nutrients found in a range of chaff cart dumps and narrow windrows. Nutrient analysis was conducted by CSBP. The legume in the example below was lupin.

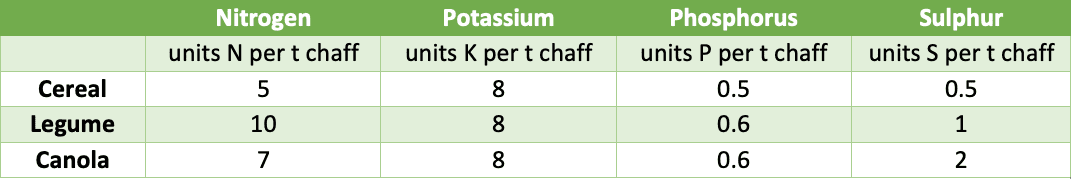

Table 2: Average nutrient content in chaff from chaff cart dumps in 2011 in Western Australia

Research by Dr Michael Walsh has shown that chaff yield averages about 33pc of grain yield. In other words, if you are harvesting a 1 t/ha wheat crop, approximately 333kg of chaff will be diverted into the chaff cart or chaff line or seed impact mill. We used this assumption to calculate the value of nutrients per tonne of grain harvested.

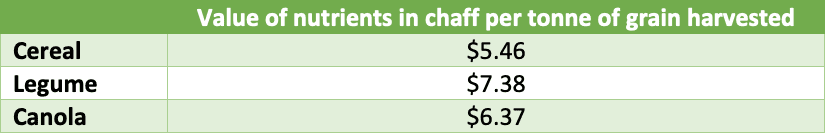

Table 3: The value of the nutrients based on 2019 fertiliser prices

100 per cent of nutrients this time

In the past we have halved the value of these nutrients when calculating the cost of nutrients in HWSC because perhaps only 50pc of nutrients applied are accessed by the crop. However, we have now counted the entire nutrient cost as this represents how much nutrient must be applied to replace what is removed. The cost of nutrients for narrow windrow burning is considered to be approximately double that of the costs of HWSC tools that focus on the chaff only. This is because approximately 50pc of crop residue is placed in a narrow windrow compared to only about 25pc for the chaff HWSC options.

Nutrient spread

For chaff lining and chaff decks, the residue is not removed from the paddock but it is placed in narrow zones that are not available to the whole crop so we assume that the nutrients are lost. The nutrient cost of seed impact mills is assumed to be zero as the pulverised crop residue is returned to the field. However, if the mill cannot evenly redistribute these nutrients perhaps we need to include this as a cost. When observing the mills it’s important to consider if they are achieving an even spread.

Cost of ownership

To calculate the cost of purchasing a HWSC tool we have added depreciation and interest rate together and multiplied by the capital cost. This was then divided by the hectares harvested by each harvester to give a $/ha cost. Consultants generally use a figure of 10% depreciation per annum for agricultural machinery. Some machinery depreciates faster, some slower. At this point in time we have no measure of how fast the weed impact mills depreciate so we have stuck with the average of 10pc. To this we have added the interest rate as there is an opportunity cost for the money used to purchase the tool.

Harvest cost

This cost is important because if the HWSC tool slows harvest in any way there is an increase in the cost of harvest per hectare. Growers should estimate their own harvest cost and rate to get an accurate measure here

Fuel

There are a range of extra fuel costs quoted for seed impact mills and chaff carts. We have used the figure of 1 L/ tonne of grain harvested of extra fuel for the mills. Growers we have interviewed have quoted anywhere from 0.3 L/t grain to 1.5 L/ tonne of grain. The 2019 harvest will provide more clarity here.

Wearing parts of impact mills

Both iHSD and Seed Terminator quote the cost of wearing parts at about $2.20 to $2.50 per hectare. Some of the factors that influence this are sand, crop type (legumes often cause higher wear rates), amount of volunteer grain fed into the mills and yield. We have used a figure of $1 per tonne of grain harvested. Growers can input their own cost based on their experience.

Repairs and Maintenance (R & M)

To be perfectly honest, this is a guess for all of the HWSC tools. We will update this as we get more accurate information.

Other benefits of residue retention

We know that there are benefits to the soil biology and moisture from retaining crop residue, however we were unable to find an accurate figure to input here. The other benefits of residue retention can be considered a bonus for the seed impact mills.

Grazing chaff cart dumps, chaff lines and chaff deck with sheep

Grazing can be both beneficial to the sheep and is likely to redistribute some of the nutrients back over the paddock. These benefits may negate some of the cost of these tools and in some cases may result in the HWSC tool being free, particularly in cases where grazing chaff dumps or lines reduces the cost of supplementary feeding of sheep.

Conclusion

There is no single answer for all grain growers as to which HWSC tool is best. It depends! This model aims to give you the most accurate estimate of cost of HWSC based on what we know now. Even though there can be big difference in capital cost between the tools, the total cost per hectare can be relatively small when all things are considered. Give the model a run with your numbers and see what you find.

Source: AHRI

Grain Central: Get our free daily cropping news straight to your inbox – Click here

HAVE YOUR SAY