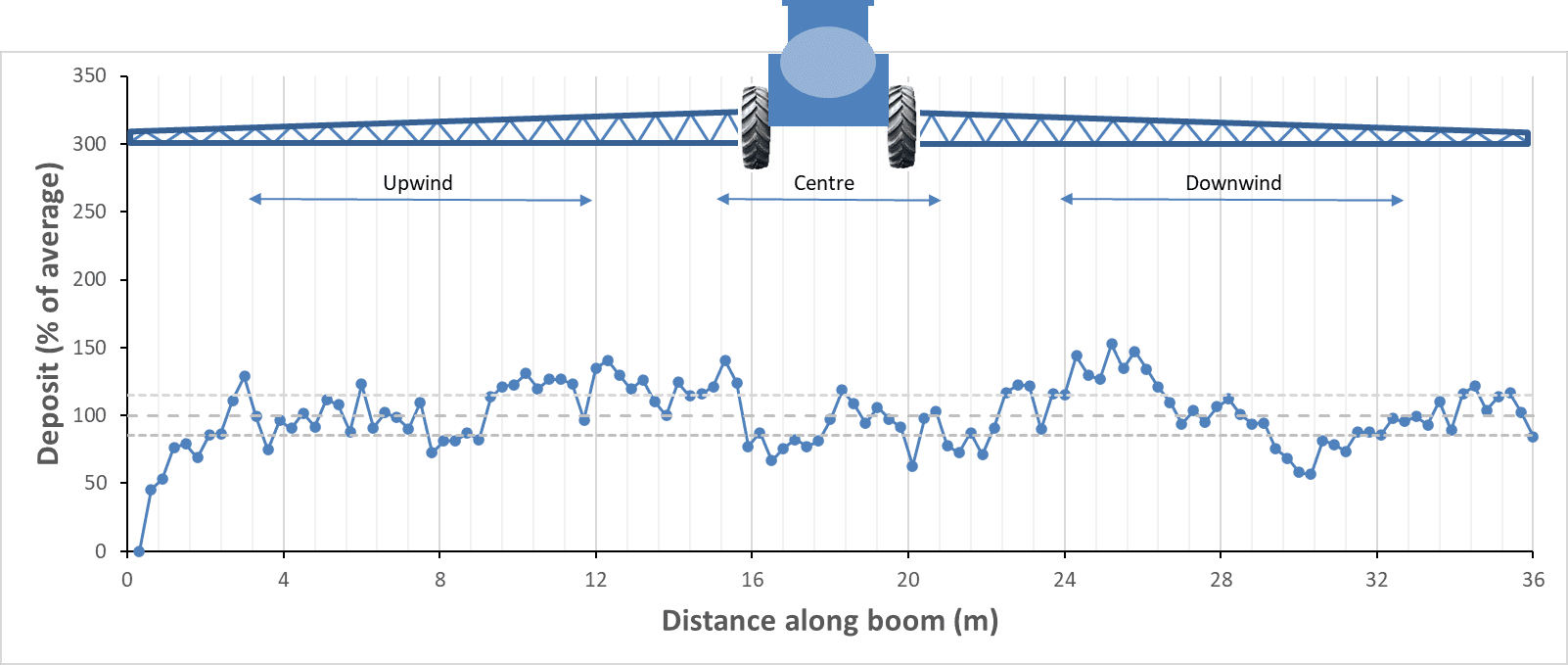

Deposit uniformity has become more of a problem with faster driving speeds and higher booms, with turbulence created by tyres also having an impact. Source: Agrimetrix

IN CANADA, as in Australia, the self-propelled sprayer is getting bigger, and as its capacity and speed increases, so does its potential to boost efficiencies in the application of crop-protection chemicals.

As the common unit becomes the 36m boom, with 48m models creeping into the mix, issues like turbulence behind wheels, boom sway and yaw, and drift from faster-moving and higher booms can all chip away at the efficacy of spray applications.

Running through these issues, and measures to counter them which have been successful in Canada, was spray-application specialist Tom Wolf from Agrimetrix Research & Training, Saskatoon, who presented at recent Grains Research and Development Corporation Updates in Perth, Bendigo, Dubbo, Goondiwindi, and Pallamallawa.

A summary of his presentation follows, which notes the trend seen also

Bouncing boom

Mr Wolf said boom design has plenty of room for improvement, now that longer units travelling at greater speeds need to sit 75-90cm above the ground to avoid damage.

Agrimetrix partner Tom Wolf has been in Australia to present at GRDC Updates.

He said some manufacturers are claiming operating heights as low as 60cm, but this would only be possible on flat country.

“Unacceptable boom sway and yaw remain as one of the inexplicable laggards in sprayer design,” Mr Wolf said.

“Few more important priorities exist, with only marginal improvements in domestic products to show for it.”

“Despite the significant capital investment required for a new spray system, overall, the success of the spray operation has been declining not just due to resistance, but also due to excessive travel speeds, boom heights, and compromises on the ideal weather operating conditions due to excessive workload,” he said of the Canadian experience.

“Key areas of attention for manufacturers should be boom stability and plumbing simplicity.

“For applicators, they should be logistics that enable slower operating speeds.”

Patchy deposits

Agrimetrix has studied spray patterns measured as a coefficient of variation (CV) as a possible negative consequence of larger units moving at faster speeds.

“Our results have been surprising, with CV of the deposit behind a 36m boom at 25kmh frequently over 25 percent and as high as 35pc.

“These results leapfrog the conventional standard for an acceptable spray deposit CV of 15pc.”

Mr Wolf said the consequence of higher-than-expected CVs is more regions of sub-optimal, and possibly sub-lethal, deposition that allow weed escapes.

“A reduction of travel speed, coupled with lower booms and coarser sprays, was found to ameliorate some of this variability.”

Pulse width modulation (PWM), which stops drips, and helps to counter pressure during turning through maintaining constant pressure in the spray line, was also part of the solution.

“We are seeing demand for PWM-compatible nozzles that is not being adequately met by most manufacturers.

“This market requires drip-free operation under rapid pulsing cycles as well as high flow-rate capability.”

Mr Wolf said sprayer travel speeds have increased, and there is increasing realisation that faster speeds are not the key to increased productivity.

In Canada, he said speeds vary from 20-30kmh, with 25kmh most common.

“The use of PWM has contributed to faster speeds as the nozzle sizing used with PWM has a built-in capacity for the extra flow required.”

Drift hard to quantify

Unlike Australia, where cotton growers in particular can quantify impacts from spray drift, Mr Wolf said Canada has not been able to document the extent of harm caused by spray drift.

“The majority of these elude the attention of a government or other reporting agency, and issues are typically resolved privately between the affected parties.”

However, Mr Wolf said studies suggest that for airborne spray drift has as much as doubled for a high-clearance sprayer travelling at 25kmh and a 90cm boom height when compared with one moving at 13kmh with a 60cm boom height.

“The increase in drift is attributed to the combined effects of boom height and travel speed, creating a trailing plume of drift that contains a larger proportion of the applied volume.

“There seems to be few mitigating actions other than lowering the boom and slowing down.

“The alternative, to use a coarser spray, while also effective, will challenge coverage, particularly since the use of contact modes of action has become more important in the age of herbicide resistance.”

Tender units used in the field to resupply spray rigs have boosted efficiency for Canadian farming operations. Photo: Agrimetrix

While bigger spray rigs fed by tenders that can refill them in the field undoubtedly offer improvements in efficiency, they can cause problems tied to their weight and tread.

“A problematic side effect of the large self-propelled sprayers is weight, with 18t dry weights not unusual.”

In Canada, Mr Wolf said tyres with 800-900mm treads are displacing the once common 650mm widths, and skinny tyres at 380mm rather than 320mm are not being as skinny as they once were.

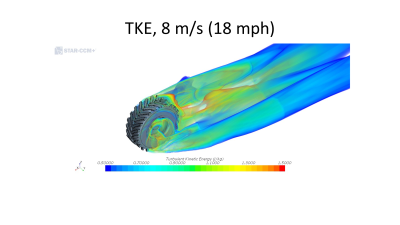

Larger tyres needed by heavier equipment introduce aerodynamic challenges that affect deposition uniformity. Image: Agrimetrix

Not surprisingly, the bigger tyres are creating more turbulence, which impacts the efficacy of spraying in their wake.

“Of note is the observation that the areas of lowest deposition occurred behind the wheels.

“Soil compaction and crop trampling are increasingly problematic, with no obvious solutions for those issues.”

Missing bang for buck

Mr Wolf said few manufacturers dominate the North American sprayer market, and further consolidation is occurring within those few companies.

“The overall diversity of offering has been stagnant, and prices have risen at twice the rate of inflation without adding as much innovation as should be expected by the price change.

“Part of the underlying cause is consolidation in dealer ownership, larger dealerships with less brand diversity, and few opportunities for independent dealer establishment owing to diluted overhead costs by large networks.

“The opportunity to bundle products for a discount, and for large farms to negotiate better deals, has created more brand loyalty within any given farm.”

Imported sprayers, such as this German-made Horsch-Leeb unit, offer superior design, particularly regarding boom stability. Photo: Agrimetrix

Mr Wolf said competition from abroad, in the form of Australia’s Agrifac since 2015, Germany’s Horsch-Leeb since 2018, and possibly Germany’s Amazone in the near future, has been welcome, and has lifted size and capacity on offer to 8000-litre tanks and 48m booms.

“These sprayers offer not only first-in class size, four-wheel steer and sophisticated wheel suspension, they also have superior plumbing designs, both in simplicity and functionality, and reasonable price points.”

However, Mr Wolf said their boom stability was the stand-out.

“Coupled with 25cm spacing, we are seeing applicators running booms significantly lower than the competition, as low as 40-50cm.

“This has advantages for drift management as well as deposit uniformity.”

Australia ahead on spot spraying

Mr Wolf said Canada lags Australia in the adoption of spot sprayers, largely because Canada’s window where green-on-brown spraying is ideal for control weeds in fallow is so narrow after winter and ahead of seeding, and a single glyphosate usually does the trick.

However, he can see potential for green on brown in Canada.

“Desiccation and pre-harvest weed control in pulse crops such as peas and lentils are a large potential use of the GoB systems, as is the application of fungicides based on a fairly high green index threshold setting.”

After gaining popularity initially in Australia’s summer-cropping regions, spot spraying is now widely used in winter-cropping only operations, with units in the hundreds across the Australian grainbelt.

Not so in Canada.

“We see approximately two dozen WEEDit systems running in western Canada.

“This system remains the performance leader and is meeting with good user satisfaction.

“Croplands has withdrawn from the Canadian market and Rometron will be taking over the marketing and distribution of the system starting in 2025.”

John Deere’s See & Spray Select has its design origins in Australia, and Mr Wolf said its sales are growing, with “many dozens of units operating in 2024 after just a few years of active promotion”.

“The main issues are basic scepticism around the performance claims for small-sized weeds, and the existing investment that most applicators have made in PWM systems that cannot be transferred to a spot-spray installation.

“They thus require a new boom and that is a deterrent.”

Mr Wolf said boom sway was an issue with both camera and nozzle systems.

“We have not seen any hints of a manufacturer offering toolbars or other wheeled booms that address these issues.”

Mr Wolf said green-on-green systems were in their infancy in Canada, with only Agrifac AICPlus units using Bilberry/Trimble software having made any inroads in the western market “with about one dozen units sold”.

“They offer algorithms in cereals, oilseeds, and pulses, as well as GoB.

“In eastern Canada, where row crops of corn and soybeans are commonplace, John Deere’s See & Spray Ultimate is selling.

“This system is not yet available for small grains and is not sold in the west.

Grain Central: Get our free news straight to your inbox – Click here

HAVE YOUR SAY