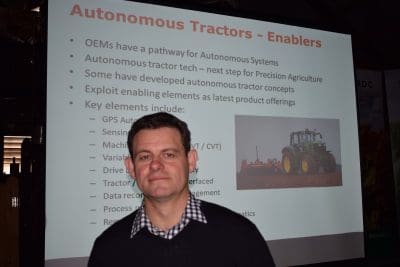

THE key ‘enabling elements’ for making and operating autonomous tractors have already been developed by the major tractor manufacturers and feature readily on existing machinery.

Auto steer, auto turn, sophisticated sensors, continuously variable transmission and variable rate technologies are all examples of existing technologies that, put together,can go to form an autonomous vehicle.

Yet, there remain significant roadblocks to the ultimate development and widespread commercial release of fully autonomous farming machines.

It’s a challenge that a project being run by the University of Southern Queensland’s National Centre for Engineering in Agriculture (NCEA) is seeking to advance.

NCEA director, Professor Craig Baillie, said the project was looking into the opportunities for autonomous tractors, primarily in the grains industry.

“We are looking to accelerate technologies that are not quite commercial yet,” he said.

“Obviously there will be some technical developments and we want to get access to these technologies, trial these technologies and demonstrate them on farm.

“But we want to use that experience to also engage with the likes of regulators, insurance people and policy people so we take out the roadblocks for the adoption or release of those technologies.”

Speaking at GRDC Updates in the northern farming zone, Professor Baillie said most manufacturers already had the key enabling components of an autonomous tractor, but were holding back from progressing to the full commercialisation of autonomous machines.

“What they are trying to do is see value out of those products by offering them now, but not as a complete form as an autonomous vehicle,” he said.

“There are certain roadblocks around an autonomous vehicle. They think they can exploit the value out of those technologies without going the final step. Our role is to try to get them over that last hurdle.”

The NCEA project has reviewed the commercial developments undertaken by the six largest tractor manufacturers (i.e. original equipment manufacturers, OEMs), John Deere, Case New Holland, AGCO, CLAAS, Same Deutz-Fahr and Kubota.

The review found that each of the major tractor manufacturers had made significant developments that formed key components of an autonomous tractor and provided a technology pathway to autonomy.

“Case released their autonomous tractor last year in the United States. John Deere released their small concept machine in 2012. So, the technology has been around for a while,” Professor Baillie said.

He said there was an opportunity for the early release of autonomous tractors in Australia by engaging with machinery OEMs to test and assess technology before its world-wide release.

“Australia provides a significant opportunity in the refinement and commercial release of these technologies and is relatively advanced in comparison to North America and Europe in the practical application of precision agriculture technologies,” he said.

Professor Baillie said manufacturers were using the enabling technologies on existing equipment as a pathway to fully autonomous systems.

“The autonomy has issues around risk and reliability. They are keen to extract most of that value out of offering everything up to fully autonomous systems,” he said.

“The large OEMs also see autonomous tractors as a next generation of precision agriculture. So, it is not just an interest in robotics and automation, but it is looking at the sort of things they are offering now in precision agriculture. They see that as the next generation in that space.

“Some companies have developed their own concept machinery to get feedback from farmers, but it has also put a lot of those things together to see how it performs as a complete package.”

Professor Baillie said another interesting development was the emergence of third-part bolt-on technologies to make current model tractors autonomous.

“Precision Makers in the Netherlands offer a kit where they can automate a John Deere tractor or a Fendt tractor,” he said.

He said there was also an emerging field of automation and robotic farming machines that were in development or in the early stages of commercialisation.

HAVE YOUR SAY