What’s the latest in the farm machinery world?

- Farm Service Manager app

- Smartfirmer seed row sensor

- Automated machinery lubrication systems

- Getting round the baler business

- Masons upgrade Morris seeder

- Nyrex bin auction to support Flying Doctor

- JD tractor upgrades

………………………………………………………………………………………………………………………………………….

Farm Service Manager app

NORTH WEST NSW farmer and innovator, David Ricardo, Morvenvale, Walgett, has developed a Farm Service Manager app where farmers can log machinery maintenance and services for all their equipment.

The new app provides the opportunity to do away with manual, book-entry farm machinery service records and transition to a digital platform that is easily updated and accessible to all on the farm.

“Farm Service Manager is a new app I’ve designed for my own farming operation that I am taking to the world,” Mr Ricardo said.

“Farmers might have spent two hours servicing a machine, changing oils and filters. When they are familiar with the app they will log that service in less than a minute.

“It is a time saver. It is about being more switched on. It is multi user, meaning any farm business can give their employees access across the board. There is nothing more important than good service records being available to a farming team. It lifts productivity.”

………………………………………………………………………………………

Smartfirmer seed row sensor

Precision Seeding Solutions owner, David McGavin, demonstrates the Smartsensor planter attachment for assessing seed row conditions.

PRECISION Planting has developed the Smartfirmer planter attachment that is primarily a seed firmer with sensors that effectively provide a ‘set of eyes’ in the sowing furrow.

Precision Seeding Solutions owner, David McGavin, Premer, NSW, said the Smartfirmer could help lift sowing efficiency and performance in all broadacre farming situations.

“It is able to look at different things in the seed trench. It looks at organic matter, moisture, temperature, residue in the trench and also looks at the evenness of the furrow, how smooth the side of the seed trench is,” he said.

“It looks at the soil type and moisture and does a calibration between the two. It gives a figure on the display of how much available moisture there is for the seed to uptake.

“On a sandy soil the water will be more available to the seed than on a heavy clay where it will be less, so we do a calibration to take that into account.”

Mr McGavin said by fitting one Smartfirme to a planter for broad control, or three for more precise coverage, an operator could use the information it generated about conditions in the sowing furrow to control the seed meter and increase or decrease seeding rates accordingly.

“It has taken away the need, to some degree, to have a variable rate map. It plugs into our control and monitoring system that interprets all the information,” he said.

“It gives you information in the cab while you are planting so you can make a decision. If you are getting a reading of low moisture or residue in the trench you can decide whether you are going to put the seed further down so it gets into moisture.

“It could be as simple as putting a couple more seeds to the metre in the soils where they don’t germinate as well to even the plants out.”

Mr McGavin said Smartfirmer would deliver the information about soil conditions into the cab and map the soils in a farmer’s paddocks.

“It won’t necessarily be the total solution, but maybe it will help you look further into your farm and identify the different soil types and decide what to do about them,” he said.

…………………………………………………………………………………….

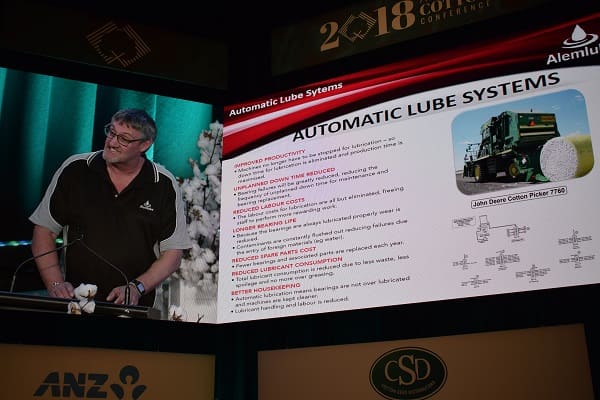

Easy greasing systems

AUTOMATIC lubrication systems have gone from being an accessory to a necessity, taking the time and effort out of greasing farm machinery, according to Alemlube’s Darrell Date.

Mr Date said the system could be plumbed into a range of agricultural machinery, including headers, sprayers, tractors and laser buckets.

“It improves productivity because you don’t have to stop your machine to grease it, taking into account it takes half to three quarters of an hour, once or twice a day to grease it manually. That can be seven hours a week of non production for that machine. Added up, the cost of the automated lubrication system can be paid for in roughly 18 months.”

Speaking at the 2018 Australian Cotton Conference, Mr Date gave the example of the how an automated system could be a big time saver for a John Deere 7760 cotton picker which had 43 grease points.

“With an automated lubrication system, those 43 points will be getting grease the whole time it is working,” he said.

“The benefit is that every half hour, or whatever you set it to, it will run for six or seven minutes, greasing every grease point on the machine. It applies a small amount of grease to each grease point at a prescribed time. The benefit is a small amount of grease is constantly pushed into the bush and bearing and allows it to keep the dust out.”

…………………………………………………………………………………………….

Claas’s new flexible cutterbar

CLAAS will release its new series of draper fronts for the range of Lexion combine harvesters at this year’s Agquip field days to be held at Gunnedah, NSW, August 21-23.

Available in working widths of 13.8, 12.3 and 10.8 metres, the new Convio series is available in both rigid and flexible configurations.

Claas Harvest Centre product manager, Jonathon Ham, said the Convio would appeal for use in cereals and canola, while Convio Flex was ideal for crops that were harvested closer to the ground, such as pulses.

Optional equipment includes left and right-mounted 425-millimetre-diameter feed augers and canola knives that can be fitted and removed without tools.

……………………………………………………………………………………

Getting round the baler business

CASE IH has made improvements to its round baler range, enhancing the precision and consistency of the machines’ performance in the paddock.

Product manager for hay and harvest, Tim Slater, said the RB5 Series variable chamber round balers had increased capacity in all crops, producing high density, perfectly-shaped bales.

The RB455 and RB465 produce bales of up to 1.5 metres and 1.8 metres in diameter respectively and both models feature a dual cylinder hydraulic density system.

“The two cylinders have 2000 psi, providing more force than a single cylinder at 2600 psi – increasing bale density and consistency across the bale, resulting in higher silage quality and better-looking bales,” Mr Slater said.

In recent updates to the series, in-cab bale density control has been introduced, making adjustments to the bale construction quicker and easier than the operator having to leave the cab.

“Depending on the individual crop and conditions, a producer may want to change the final bale profile, and the end-purpose of the bale can also be a determining factor in the bale core density,” Mr Slater said.

The operator can quickly and simply swap from a soft core bale to be put through a feed mixer to a well-rolled hard core bale to be rolled out.

Another update to the RB455 and RB465 has been a change in the sledge and tailgate rollers, a big improvement for the operator in that it significantly reduces the clean-down time, maximising in-field efficiency.

…………………………………………………………………………………………..

Masons upgrade Morris seeder

NSW grower Matt Mason, Spicers Creek, and McIntosh Distribution’s Geoff Anderson with the 9.45-metre Morris CX 8105 seeding system. It is set on 25-centimetre (10-inch) tyne spacings and is fitted with Agmaster points on a paired row configuration for more even sowing depth.

THE Mason family who farm near Wellington in central New South Wales have upgraded their seeding system to improve breakout and trash flow on their undulating country, taking delivery of a 9.45-metre Morris CX 8105 seeding system in April.

Matt Mason said they had previously used a C1 Contour drill on 30-centimetre (12-inch) spacings, before upgrading to a C2 Contour on 25cm (10in) spacings with a paired row setup.

“We have a lot of undulating country here and so the compact nature of the CX was very appealing,” he said.

“We also wanted better breakout and trash flow, which we got with the CX. It’s been really good and we’ve seen a big improvement.”

Mr Mason said the Morris CX 8105 combined the benefits of the Contour precision drill with seed metering and air cart technology, in a compact design.

The CX 8105 is available in 7.62m (25-foot) or 9.45m (31ft) working widths, with the choice of 25cm (10in) or 30cm (12in) row spacing.

………………………………………………………………………………………

Nyrex bin auction to support Flying Doctor

This custom-painted Nyrex chaser bin will be auctioned to raise money for the Royal Flying Doctor Service.

FARM machinery manufacturer GrainKing is to auction a specially-built, 40,000-litre Nyrex chaser bin to raise money for The Royal Flying Doctor Service (RFDS) which is celebrating its 90th year anniversary in 2018.

GrainKing will manufacture the Nyrex chaser bin which will be donated to the RFDS and auctioned at the Dowerin Field day in Western Australia on Wednesday August 29.

The Nyrex chaser bin would normally sell for $97,900 and is hoped to raise a profit of $60,000 to $70,000 which will all go to RFDS.

GrainKing CEO, Colin Jorgensen, said the business worked extensively across all the grain growing areas of Australia which made it a natural fit with the RFDS, one of the largest and most comprehensive aeromedical organisations in the world.

The service provides extensive primary health care and 24-hour emergency service to people over an area of 7.69 million square kilometres.

The Nyrex chaser bin will be auctioned online and onsite by Smith and Broughton Auctioneers.

…………………………………………………………………………………………

JD tractor upgrades

AutoTrac automatic guidance is included in base equipment on John Deere Series Four Track tractors for model year 2019.

JOHN Deere will release several updates for model year 2019 to its large 9R, 9RT, and 9RX tractors that include a mix of the latest technology and performance-enhancing features.

For the first time, the company is offering a 3.05 m (120-inch) track spacing option on 9470RX, 9520RX, 9570RX and 9620RX Series Four Track Ag Tractors equipped with 76.2 cm and 91.4 cm (30- and 36-inch) tracks.

“The extra wide stance of this machine is ideal for customers wanting to control traffic patterns and enhanced stability on hilly terrain,” John Deere product marketing manager for large tractors, Tiffany Turner, said.

John Deere is also offering the option of a factory- or field-installed Hydraulic Intelligent Power Management (IPM) system to boost tractor performance when operating implements requiring continuous hydraulic power.

“Hydraulic IPM is specifically designed for air seeding operators using large drills and air carts on their farms,” Ms Turner said.

“Hydraulic IPM provides an extra 25 horsepower in gears 5 thru 18 and adds 50 more horsepower in gears 1 thru 4, enabling the tractor to pull heavy loads through tough conditions.”

Sources: Claas, Case IH, John Deere, Mason, GrainKing.

Grain Central: Get our free daily cropping news straight to your inbox – Click here

HAVE YOUR SAY