IT WOULD be remiss to talk about the latest integrated Harrington Seed Destructor (iHSD) research without acknowledging the challenges with this new machinery during the 2017 harvest.

It was frustrating for everyone, but the researchers, manufacturers and suppliers are playing the long game. They are dedicated to succeeding in the long run.

It was frustrating for everyone, but the researchers, manufacturers and suppliers are playing the long game. They are dedicated to succeeding in the long run.

Developed from the original, tow-behind Harrington Seed Destructor, the iHSD is designed to be installed in a combine harvester, rear of the sieves, where it destroys weed seeds in the harvest trash as it passes through the machine.

Recent research by Michael Walsh commenced at the Australian Herbicide Resistance Initiative (AHRI) and was completed at Sydney University with help from John Broster at Charles Sturt University (CSU).

It shows that despite the problems that have been experienced with the new machines, the iHSD mills are passing the research tests with flying colours.

The research concluded that:

- The iHSD achieved 96-99 per cent destruction of the seeds of 11 weed species when processed in wheat chaff;

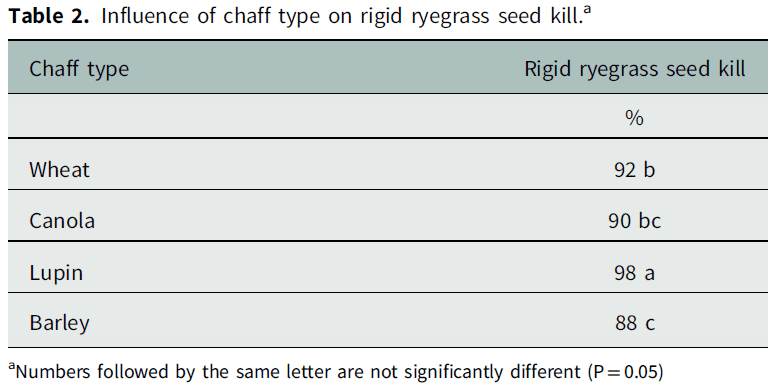

- Weed seed destruction varied by about 10pc depending on crop chaff type – ryegrass seed kill was greatest in Lupin (98pc) > Wheat (92pc) > Canola (90pc) > Barley (88pc);

- Weed seed kill dropped by about 4pc when chaff moisture increased above 12pc; and

- Weed seed kill increases with mill speed and 3000rpm is the accepted optimal speed.

Michael Walsh from the University of Sydney (formerly AHRI) and John Broster from CSU have spent many hours sifting through huge bags of chaff laced with coloured weed seeds to confirm the iHSD works on a large range of weed species under a range of conditions.

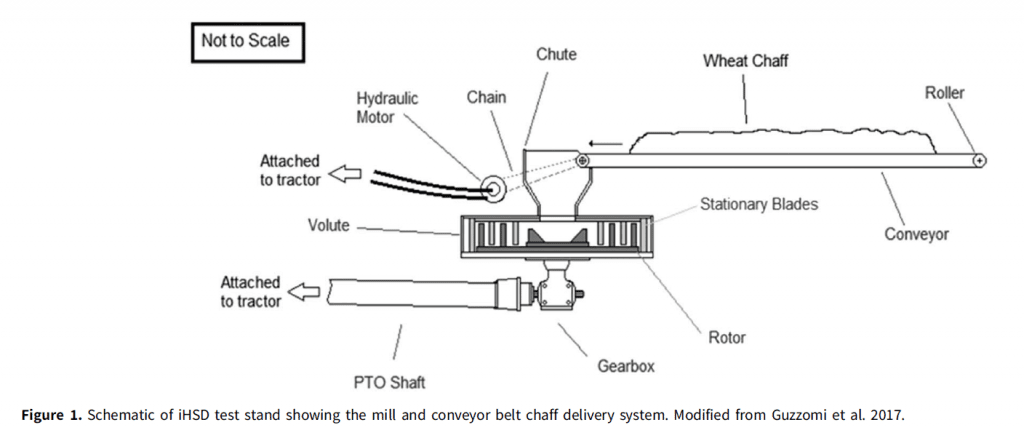

Readers don’t generally care too much for scientific methods so we won’t go too deep into the detail, but it’s important to know this research was done using a stationary test mill as shown in Figure 1.

Chaff laced with coloured weed seeds is placed on a conveyor belt that is fed into an iHSD mill with the processed material caught in a mesh bag.

A team of eager, well-paid students then spent months sifting through bags of chaff to find any weed seeds for germination testing to see if they had survived their trip through the mill.

How much chaff?

The amount of chaff used in the testing has been calculated to simulate harvesting wheat at 35 tonnes/hour.

For every tonne of wheat grain harvested about 300 kilograms of chaff is produced.

Therefore, when harvesting 35t/hour, 10,500kg of chaff is produced per hour.

Each mill in a twin-mill iHSD system must therefore process 1.5kg chaff/second.

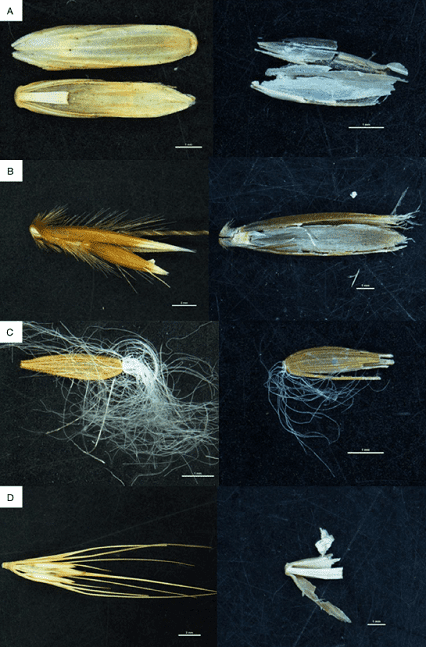

This picture shows the damage inflicted on weed seeds from the iHSD mills. HSD mill unprocessed (left photo) and processed (right photo) seed of (A) Lolium rigidum, (B) Avena fatua, (C) Sonchus oleraceus, and (D) Hordeum vulgare.

Eleven Australian weed species tested

Previous research has focused on four key Australian weed species. This study dug a little deeper and found that the iHSD mill was effective on 11 different weed species as can be seen in the table below. Other international studies are currently underway assessing weed kill of a wide range of species, with encouraging results.

The effect of crop type

The effect of crop type

Table 2 shows that there are small differences in ryegrass seed kill between four crop types.

However, other trials conducted in the field during commercial grain harvest achieved 99pc kill of ryegrass, wild radish, brome grass, and wild oat while harvesting canola or barley.

Essentially it is fair to say that the iHSD mill is effective in all crop types tested so far.

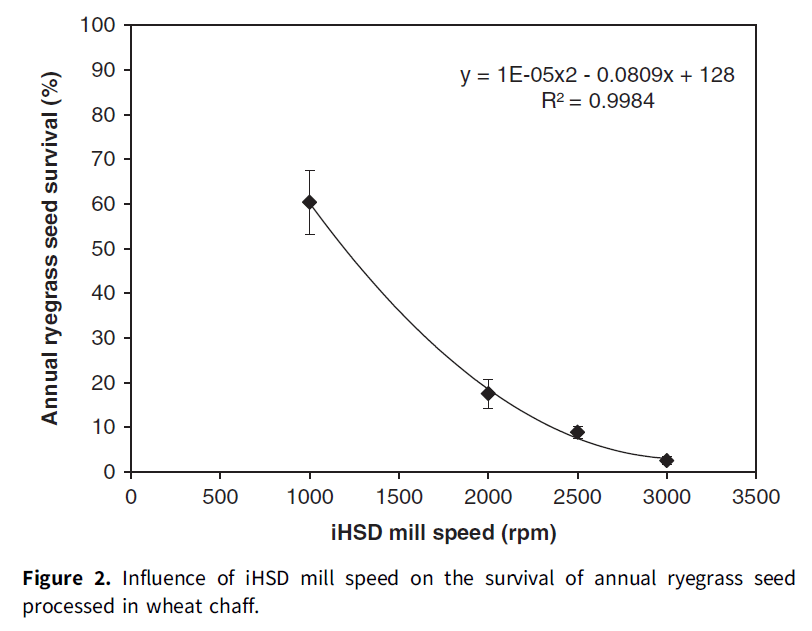

Mill speed

A small increase in mill speed requires a large increase in horsepower to drive the mill, so we need to make sure we are not overdoing it or we will be costing growers time and money with no additional benefit.

Figure 2 shows how the researchers and developers of the iHSD, DeBruin engineering, settled on the 3000rpm mill speed.

Moist chaff reduces seed kill

Moist chaff reduces seed kill

The researchers measured ryegrass seed kill at 10, 12, 14 and 16pc moisture.

Seed kill was 92pc at the lower moisture levels (10 and 12pc) and dropped to 88pc for the higher moisture levels (14 and 16pc).

Summary

The iHSD had some challenges with bearings and excessive wear of the mills, amongst other smaller issues during the 2017 harvest, but we shouldn’t lose sight of the big picture. The research is outstanding, the challenge now is to ensure that the machinery develops into a reliable, effective tool, because a large portion of the world’s crops need it.

……………….

Source: Australian Herbicide Resistance Initiative, http://ahri.uwa.edu.au/

This article first appeared in AHRI Insight.

………………..

Further reading:

iHSD Mill Efficacy on the Seeds of Australian Cropping System Weeds

Harrington Seed Destructor: A New Nonchemical Weed Control Tool for Global Grain Crops

Grain Central: Get our free daily cropping news straight to your inbox – Click here

HAVE YOUR SAY