RUSSIAN machinery designers are set to begin the large-scale introduction into the field of the Cognitive Agro Pilot system, an autonomous driving system for agricultural machinery, including harvesters, tractors and sprayers.

The project is being undertaken by Rusagro, Russia’s largest agricultural holding company, and Cognitive Pilot, an autonomous driving technology joint venture of Russia’s Sberbank and Cognitive Technologies Group.

Proponents claim the project is the world’s largest one-time robotisation project for agricultural machinery in four climatic zones within one agricultural holding.

The Cognitive Agro Pilot software and hardware complex will be installed on 242 combine harvesters used by Rusagro in the Belgorod, Tambov, Kursk and Orel regions, as well as in Primorsky Krai.

The machinery will be equipped with the system progressively over the 2020-21 harvest. The first will be installed in the middle of June.

The partnership between Rusagro and Cognitive Pilot is being carried out within the federal project “Digital Technologies” (part of the national program “Digital Economy of the Russian Federation”), which is implemented by the Skolkovo Foundation.

Rusagro’s chairman, Vadim Moshkovich, said equipping the fleet of harvesters with an AI-based autonomous control system would significantly enhance the efficiency of harvesting.

“Improving the efficiency of agricultural enterprises through the use of the latest technologies of autonomous driving will lead us to a new level of productivity – a new quality of work for the entire Rusagro team,” Moshkovich said.

Rusagro Agriculture Business Division chief executive officer, Roman Shkoller, said the use of an autonomous control system during harvesting would minimise the risks of negative human factors and would optimise the use of the harvesters.

“It’s noteworthy that the industrial introduction of the system fell in a year when a record harvest of wheat is expected in Russia. We have used all the necessary resources to show a decent result at this year’s harvesting campaign,” Shkoller said.

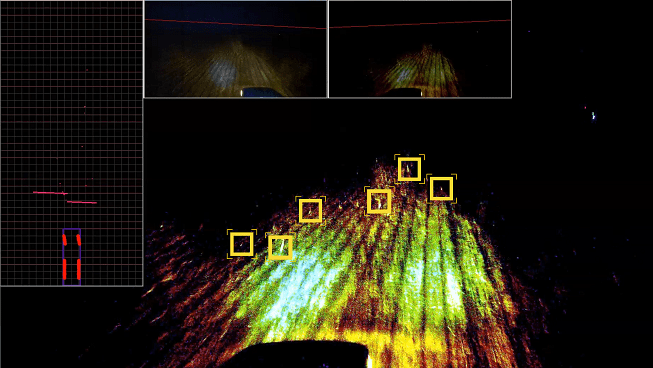

According to the signed specification, the system will be capable of performing safe autonomous movement in ploughed or unploughed ground and mowed or unmowed fields.

The system will also automatically detect obstacles and warn the operator when the machine leaves the route in cases of manual operation.

Operators will also be able to monitor the movement of each equipped machine on the track in real time.

Operators will also be able to monitor the movement of each equipped machine on the track in real time.

“The presence of an operator in the cabin during harvesting will still be mandatory. However, the system will allow the operator to focus more on controlling and monitoring other parameters of the harvesting process: for example, on the angle of the header, setting the threshing process and grain cleaning,” Cognitive Pilot CEO, Olga Uskova, said.

“The edge grip while operating with the Cognitive Agro Pilot is stable, it does not exceed 20 centimetres to avoid excessive passages and fuel losses. In general, the use of the system can reduce the cost of grain by 3-5 per cent and reduce its losses during harvesting by two times. In the future we plan to develop a fully driverless system.”

Source: Cognitive Pilot

HAVE YOUR SAY