MSM Milling’s site at Manildra which will be the location of a major expansion.

THE GROWING demand for renewable fuels and changing diets in South-east Asia is driving increased investment in Australian canola-crushing facilities.

Currently, Australia has a tiny canola crush capacity, estimated by USDA to sit at 1.2 million tonnes (Mt), compared to the global output predicted to be 81.1Mt in 2023-24.

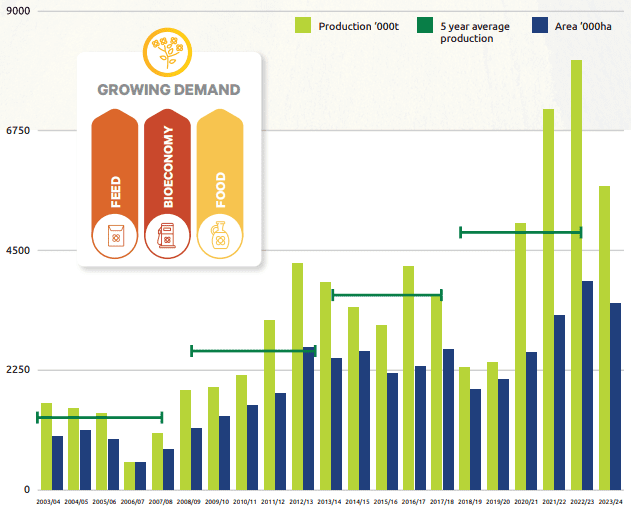

However, Australia’s canola industry has flourished in the past 25 years, going from producing 2.5Mt in 1999 to a record 8.3Mt in 2022-23.

By comparison, Australia’s biggest competitor, Canada, produced 18.17Mt of canola in 2022 and crushed 9.96Mt in 2022-23.

Significant new investments are afoot to increase the crush capacity, as the majority of Australia’s canola production is currently exported as seed.

A key reason for this gap is the lack of crush capacity in Western Australia and South Australia.

WA produces almost half the national crop but only accounts for around 10 percent of Australia’s total crush, according to USDA’s Oilseeds and Products Annual report released in April.

In addition, very little of SA’s estimated 500,000t 2023-24 crop will be processed onshore.

Australian Oilseed Federation executive officer Nick Goddard said this disparity means Australia was not economically benefitting from value-adding the commodity.

“It is a bit unfortunate that over the past 30 years or more, all we have done out of WA effectively is seed,” Mr Goddard said.

“I think the opportunity to provide value-added processing in WA is great.”

Major expansion for MSM

Family-owned canola oil processing company, MSM Milling, is one business leading the way in boosting Australia’s crush capacity.

The company recently announced plans for a major expansion at its Manildra plant in central New South Wales which would nearly double the site’s production capacity and improve oil yields.

The development will feature construction of a new solvent-extraction plant, a rail-intake upgrade, and new infrastructure.

MSM Milling’s current plant uses mechanical pressing to produce canola oil and meal.

The expansion will see the company incorporate solvent-extraction technology in its operation which will increase the amount of oil extracted from the canola seed.

MSM Milling director Bob Mac Smith said the demand for canola products for the food and fuel markets were only growing.

He said it was clear that now was the right time to invest in the company’s infrastructure and output capacity.

“There is a compound annual growth rate in the oilseed industry of three or four percent,” Mr Mac Smith said.

“Over a period of time, there has been this organic growth in the demand for the products.”

MSM Milling manufactures oils and meals primarily for the domestic market targeted to industries including food manufacturing, food service, quick-service restaurants, and retail.

“We’d be aiming to continue to grow those markets but also, we do export and anticipate that we will export more.”

Construction on the expansion is scheduled to begin this year, with final commissioning anticipated in 2025.

Canola production and area compared with the five-year average. Source: Australian Oilseeds Federation

Industry expansion

Most of Australia’s canola crush capacity is on the east coast.

The two largest industry players are ASX-listed GrainCorp, which operates a large plant at Numurkah, Victoria, and a medium-sized facility at Pinjarra, WA, and global agribusiness Cargill, which owns a site at Newcastle, NSW, and Footscray in Victoria.

Apart from MSM Milling and Cargill, crushers in NSW include Riverina Oilseeds at Bomen, Cootamundra Oilseeds at Cootamundra, and CMP Oilseeds at Griffith.

Additional national capacity comes from Victoria’s Windermere Oilseeds in Windermere, Aus Oils in Kojonup in WA, and the Squib Group in Millicent, SA.

In Qld, PB Agrifood crushes small quantities of canola with other oilseeds, such as soybeans.

Alongside MSM Milling’s expansion, both Cargill and GrainCorp last year revealed major plans aimed at increasing Australia’s oilseed crushing capacity.

In April, Cargill announced a $73 million investment in its oilseed crushing sites, which will include upgrades to its Footscray plant to increase canola-crush capacity as well as targeting more cottonseed outputs via reopening its mothballed Narrabri site and upgrades at the Newcastle facility.

Last year, GrainCorp announced that WA was the preferred location for a new crushing plant which would have an approximate capacity of 750,000-1Mt.

Still subject to the results of a feasibility study, this project would substantially increase the crush capacity of WA, currently estimated at about 60,000t.

This investment has come on top of other developments, including a doubling of capacity over the past five years at GrainCorp’s Numurkah plant, and the formation of the Squib Group in 2020, bringing a crusher service back to SA.

Mr Goddard said these projects were testament to the stability and viability of the canola industry long term.

“What it demonstrates to me…is that the industry, including the global multinationals like Cargill and ASX-listed companies like GrainCorp, see a very buoyant future for the industry,” Mr Goddard said.

“They see value in investing in Australia, which is a really good sign.”

GrainCorp’s crushing plant at Numurkah in Victoria’s Goulburn Valley.

Growing international markets

Mr Goddard said the increasing western influence on South-east Asian diets and growing population centres on the sub-continent were drivers of increased investment in canola-crushing facilities.

He said this dietary shift and proximity to Australian ports made this a logical market to target for growth.

“As the Asian and South-east Asian nations continue to develop and become more westernised, they start to consume more vegetable oils and within that healthier vegetable oils.

“Looking out to say 2050, the Indian sub-continent and the entirety of the sub-continent will be a huge opportunity for us as well as the South-east Asian market.”

Mr Mac Smith said he anticipated that South-east Asian markets would be a key export destination for MSM Milling into the future.

“[Exports] will be more Asian focused simply because of logistics.

“Canola has a very desirable fatty acid profile…so from a health perspective it has a great fit in most diets.”

Feedstock for fuel

Mr Mac Smith said the global demand for renewable diesel and the burgeoning interest in sustainable aviation fuels were a key factor behind the recent investments in canola crushing capacity.

“The big driver on a global scale is the massive increase in the demand for feedstock for green diesel or renewable diesel.

“The demand for feedstock is enormous, almost insatiable, and add to that this growing demand for sustainable aviation fuels.”

Mr Goddard said the European Union is a major destination for Australian canola, with the region importing about 3.4Mt of seed and 400,000t of tallow in 2022.

“The European Union is not letting up in their buying for biodiesel and we are also seeing the United States open up the demand for canola oil for biodiesel.”

According to CSIRO’s Sustainable Aviation Fuel Roadmap released in August, approximately 60pc of these imports will be used for biofuels.

Mr Goddard said the “impending demand for SAF” would also be a driver of future growth for the canola and oilseed crushing industries.

GrainCorp has signaled its interest in entering the SAF market, signing a memorandum of understanding with IFM Investors aimed at exploring the use of agricultural feedstocks to produce SAF.

The initiative will include an initial feasibility study for a SAF facility capable of producing a targeted 720,000t of renewable fuels annually.

“The need for SAF continues to grow and, here in Australia, we have a significant opportunity to be at the forefront of global feedstock and renewable fuel supply,” GrainCorp CEO Robert Spurway said.

Oilseeds, such as canola, are one feedstock which could be used to produce SAF.

There are no SAF manufacturing plants currently operating in Australia; however, BP and Oceania Biofuels have announced plans to open facilities in Perth and Brisbane.

These plants are expected to import used cooking oils as the primary input, but canola could be used as a supplementary feedstock.

Get our free news straight to your inbox – Click here

HAVE YOUR SAY