APP co-founder Phil McFarlane at the company’s sheds in Horsham. Photo: Liz Wells

AUSTRALIAN Plant Proteins (APP) co-founder Phil McFarlane said the company’s goal is to continue using locally-grown, sustainable raw products, and future processing facilities, including the recently announced development at South Australia, will be strategically located close to pulse-growing areas.

The plant-based powder processing, packaging and distribution business uses a mixture of faba beans, lentils, mungbeans, yellow peas and chickpeas to produce protein isolates.

Mr McFarlane said faba beans were currently the company’s “anchor protein”.

APP has the only large-scale commercial plant-protein fractionation facility in Australia, located at Horsham in Victoria.

Mr McFarlane told the CSIRO Complimentary Proteins webinar this week that most of the raw material it processes at Horsham is sourced from the local region.

“The only thing we have outside an 80-kilometre radius of Horsham is mungbeans that we bring down from southern Queensland,” Mr McFarlane said.

“Nothing comes internationally.”

He said the Horsham facility, completed in 2020, was strategically located to capitalise on the already established pulse-growing industry in the region.

“It is the gateway in Victoria to where our pulses are grown from here all the way back into SA.

“We are big on building our facilities where customers can come to us and see where the farmers are too and get that authentic feel of the farmgate through the production facility.”

SA facilities to be regional

Mr McFarlane said APP used the same principle when considering sites for the three recently announced facilities set to be located in SA.

The project is in partnership with Thomas Foods International and Australia Milling Group.

He said the “main leader” is a regional location north of Adelaide.

“It will be a regional area…and will keep with our principles of being close to the farmers.”

Mr McFarlane said the new facilities will process a range of pulses.

“We will build three individual lines that will do 8000t each and they will have a minimum of three varieties, whether that be faba beans or lentils or peas.

“One of those lines will have separators that do chickpeas.”

Demand gap exists

Mr McFarlane said the goal of APP is to continue working with farmers to grow pulses that suit the needs of the booming plant-protein market.

He said taste, appearance and texture of the isolate powder means it can be used in a wide variety of products from baking, protein powders and bars to meat and dairy alternatives and plant-based eggs.

He said pulses grown by farmers did not need to be altered to fit APP’s requirements.

“I like the process where we don’t look at the variety, because they all perform very similarly which is great.

“Most of the varieties [farmers] have work perfectly; we don’t want to break something that isn’t already broken.

“We want to work with them as partners.

“They are part of our value chain and, therefore, we can price-reward them for continuing to grow great pulses.”

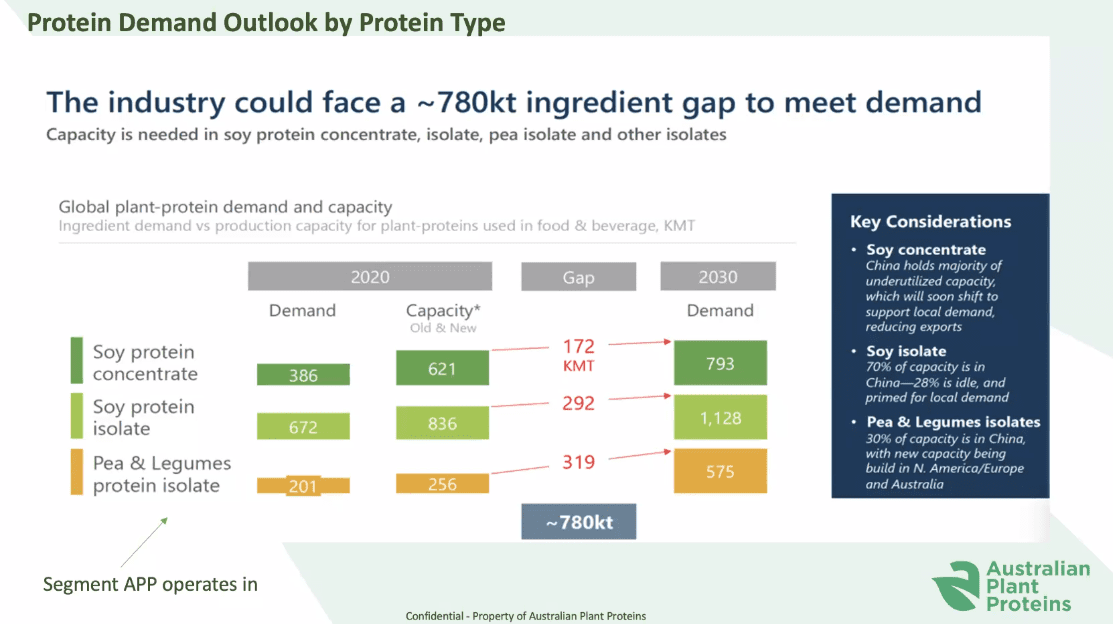

The predicted ingredient gap for the global demand of soy protein concentrate, isolate, pea isolate and other isolates. Photo: APP

Mr McFarlane said projections for the growth of the plant-protein industry offered exciting opportunities for Australian farmers.

He said the soy, pea and legume-protein concentrate and isolate markets had a substantial ingredient gap to meet the predicted 2030 demand.

“Even in just these categories, there is something like 780,000t that needs to be produced to fill the gap, let alone meet the growth.

“I think that’s the exciting part within the grains industry.”

Sustainability is key

In addition to producing an ideal product to manufacture protein isolates, Mr McFarlane said Australian farmers grow clean, sustainable pulses that suit the needs of APP’s customers.

He said sustainability, in terms of low water usage and prioritising renewable energy and recycling principles, all makes Australian products attractive to his customers.

“We have a great sustainability story for our pulses from farmgate all way through to ingredient.

“Australian farmers have been growing pulses sustainably for decades.

“In the millennial drought lentils alone doubled.

“They can grow them in lower rainfall, less moisture; but they were growing them just to protect their wheat and barley, where as they can grow them and we can reward them for that.”

Mr McFarlane said APP has also been building sustainably traits into their facilities to further strengthen this proposition.

He said all by-products of the production process are re-used in some way, including the water which is recycled and piped back into the system.

“With our starch carbohydrate, roughly every day there is circa 26 or 27t that we send from Victoria into New South Wales to a feedlot who mix it into their cattle ration.

“The carbohydrate is great for the digestibility for fattening up beefys, so we have a market for that.”

As part of APP’s processes, it takes 5t of raw pulses to produce 1t of plant-protein isolates.

Currently APP produces about 1500t of protein isolates annually at their Horsham site.

The second line of the Horsham facility, which is currently in construction, will manufacture a further 5500t each year.

This is in addition to the predicted 25,000t which will be produced at the South Australian sites.

Grain Central: Get our free news straight to your inbox – Click here

HAVE YOUR SAY