MOUSE bait spreaders are proving an essential investment for farmers battling to control a severe outbreak of the pest in eastern Australia.

A range of commercial and farm-built spreaders has been pressed into service throughout the cropping regions as producers work to limit mouse damage to summer crops and head off their potential impact on the forthcoming winter crop planting.

Farmers should consider mouse bait spreaders an essential part of their farm equipment inventory.

CSIRO research officer and mice control expert, Steve Henry, said mouse bait spreaders were a valuable, long term investment which every farmer should have in their farm equipment inventory.

“Mice are going to be an ongoing problem as we continue to grow better crops and make an environment that is favourable to mice,” he said.

“Farmers are going to need spreaders more often, so they might as well invest in one that does the job properly. Most cost between $3000 and $7000. If you are doing it every year, the alternative is resowing your crop which just doesn’t compare.”

Mr Henry said the most important thing to look for in a spreader was its capacity to evenly distribute the zinc phosphide-coated grain bait across the target area.

At the upper end of the market, he said there were commercial spreaders that utilised GPS to adjust to the tractor/machine speed and vary the output accordingly.

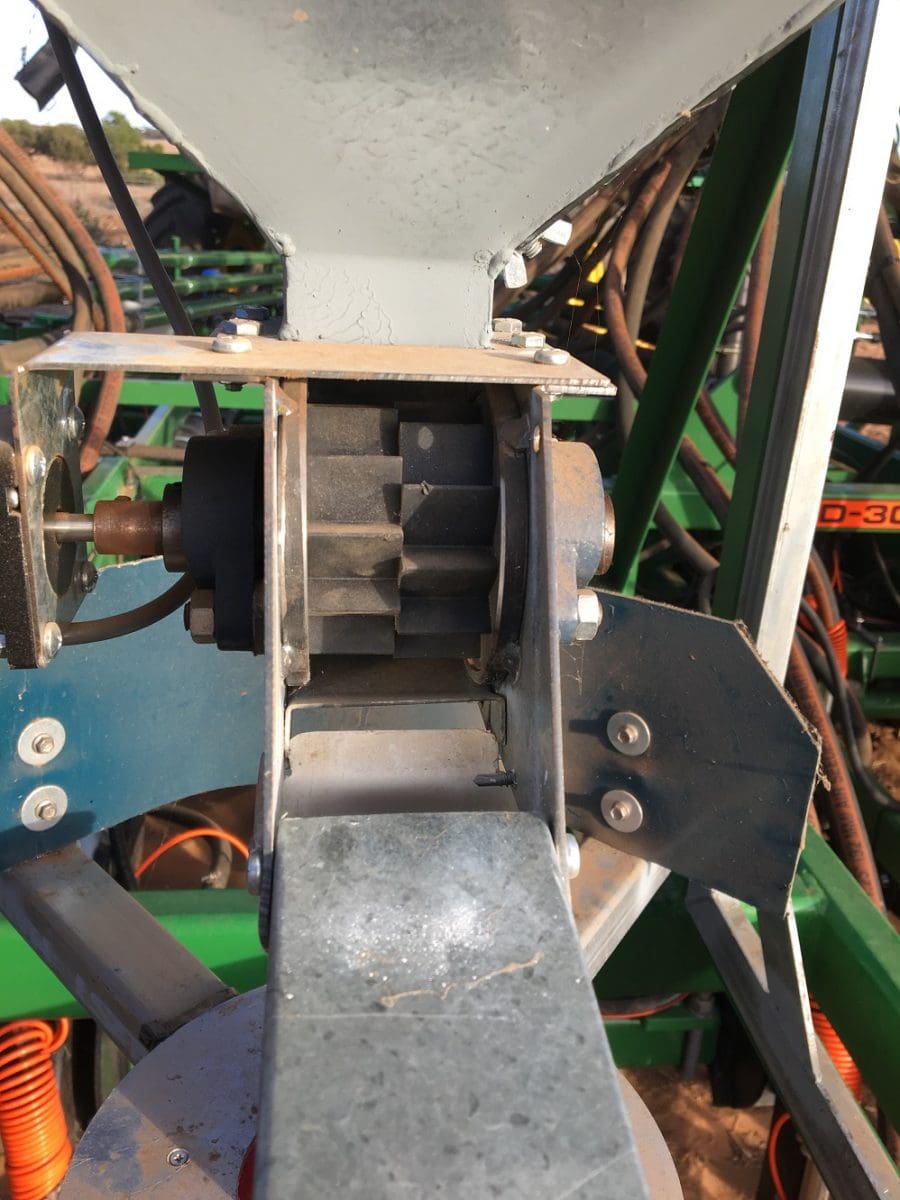

“I know of a specific mouse bait spreader that works off a vertically turning cog at the bottom of the hopper. It picks up the grain out of the bottom of the hopper and drops it onto the spinner. The machine is set up so it can be wired into the GPS in the tractor so that as the tractor slows or turns the machine meters the rate according to the tractor speed,” he said.

Farm-built alternatives

Mr Henry said the alternative to purchasing a purpose-built machine was for farmers to build their own or adapt existing farm equipment.

These included rigging spreaders behind their airseeders and utilising the seeders’ small seeds boxes.

Whilst this can be done successfully, he said there were many challenges and potential problems producers needed to be aware of.

“I’ve seen people try to put it out through super spreaders and a whole range of other non-specific spreaders,” he said.

“You get issues with bait churning above the spinners. The zinc phosphide is stuck on the surface of the grain with oil. The churning leads to the zinc phosphide being sloughed off the grain. It is not going out into the paddock where it should go.”

Mr Henry said there were many instances where farmers had issues with spreaders set up on the back of their seeders.

“The complaint is they get out to fill the seed bin and find the mouse bait hopper is either full, meaning it hasn’t been spreading at the right rate, or empty and I haven’t got a clue about when it went empty,” he said.

“One thing farmers could do is rig up a camera on their mouse bait hopper so they have some idea of what is going on when they are spreading the bait.”

Low rate challenge

Mr Henry said the main challenge with home-built spreaders was being able to reduce the aperture to a small enough diameter so the bait was spread at the very low rate required.

In a baiting program, zinc phosphide-coated grain must be applied at the label rate of 1kg/ha across the paddock, excluding a 50-metre buffer zone to the edge of the crop and any native vegetation. The rate equates to around two to three bait seeds per square metre.

“In terms of altering your air seeder’s small seeds bin and hitting the spreader plate at the back of the machine, it sounds like a good option to me if you can get your metered rate absolutely right,” he said.

“If you can tweak your airseeder so you are just putting bait out behind the last press wheel that would work really well because the mice would follow along the freshly tilled line and will take bait off the surface in preference to digging for freshly sown seeds.”

Further reading:

Grain Central story, 2017, ‘Farm-built baiting innovations’

Grain Central story, 2021, ‘Farmers ramp up strategies to tackle mouse outbreak‘

GRDC ‘Baiting mice: equipment set up a key to success rate’

GRDC ‘Mouse control is now a year-round activity’

Grain Central: Get our free cropping news straight to your inbox – Click here

HAVE YOUR SAY