PROTEIN sensors that assess grain quality as it is taken into the harvester are among a suite of sensing technologies that are yet to be utilised to their full potential by the Australian farming sector, according to University of Sydney associate professor of precision agriculture, Brett Whelan.

Associate professor Whelan said nowadays virtually all forms of production assessment from yield monitoring to grain protein, oil and moisture assessment could be carried out “on the run”.

“There is value in the protein content, yield data and moisture content that sensors are providing that farming is not yet recognising,” he said.

“Protein monitors, alone, can provide information for optimising marketing options and for analysing what you have done.

“If you put protein together with yield and moisture monitoring, you can start to look at where the economics is falling down in the process.

“Down the track, as we get better at dealing with all the data, it is going to be very, very useful.”

Speaking at Grains Research and Development Corporation Updates, associate professor Whelan said monitoring the quality of grain in real-time during harvest provided opportunities for growers to segregate or mix grain based on quality.

“There is a simple use in terms of being able to do a more controlled blending of grain at harvest,” he said.

“There is a big variation in protein within fields. Even though the harvester may blend it together and you are marketing it across the average, there are parts of a field where the protein may be way below that.

“Those areas are dragging your whole average down. You can segregate those areas out, or you can blend them in better so you aren’t penalised. Some loads you might harvest the part of the field that is low in protein, store it, then blend it afterwards.

“Identifying areas within a field or farm where wheat grain with specific protein levels can be harvested may provide premium marketing and increased profit opportunities. You can segregate to store the really good stuff for marketing later when the prices are better.”

Associate professor Whelan said another significant benefit of monitoring protein and collecting other on-farm sensing data was the opportunity to better manage nitrogen.

“The value of it is you can get a much better insight into what is happening with the interaction between nitrogen, storage of water in the soil and crop use,” he said.

“In managing agronomic programs, they give you benchmarking, an understanding of what is changing and allow you to understand nitrogen better. There is a unique opportunity to add value.

“It is the water interaction between nitrogen, moisture and soil type during the growing season that drives the concentration of protein content in cereals.

“If you are changing your nitrogen application but can’t keep track of what it is doing to grain quality, then there is an agronomic and marketing hole in your system.”

Associate professor Whelan said protein sensors were currently an option on Case headers, and could be retrofitted to any existing harvesters.

He said wheat was the biggest market for protein sensing, but there were calibrations for a range of crops including barley, rice and canola.

He and his team at the University of Sydney have been working with two sensors: United States-based Zeltex and Australian-manufactured Next Instruments.

“They both take a sub-sample out of the grain elevator as the grain goes up, make it stationary, measure it and return it to the downside of the elevator,” he said.

“They measure light transmittance. The light passes through the grain and a near infra-red (NIR) sensor measures the protein, moisture and oil.

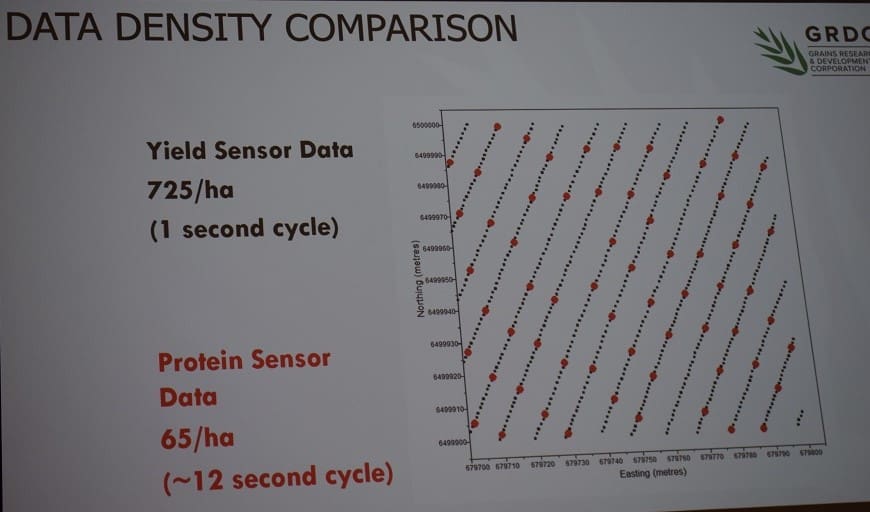

“Taking a sample every 10 to 12 seconds you end up with roughly 65 observation points per hectare.”

Figure 1: Grain yield data gathered on-harvester once every second (smaller black dots) and grain protein content data gathered in the same harvest operation every 12 seconds (larger red dots).

Associate professor Whelan said compared to grain testing at public silos, on-board harvester sensors might not be as sophisticated but took far more samples that gave a better cross-section representation, “so you will be way ahead of the game”.

“If you take a truck into the town silo with 10 tonnes of grain and they vacuum a few spears out of it to put into a 400-gram sample, you get one estimate of protein per 10 tonnes,” he said.

“With a protein sensor on the harvester, if you are harvesting a three tonnes/hectare crop, you get 200 observations of protein for that load, not one.

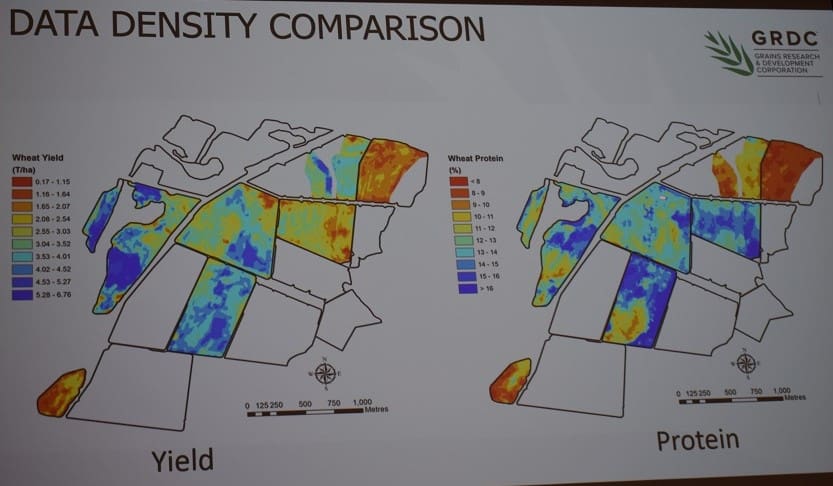

“Protein sensors nowadays are quite good. They allow you to make protein maps that are the same resolution as yield data maps.”

Figure 2: Spatial pattern of wheat grain yield and wheat grain protein content across a farm in northern NSW.

Associate professor Whelan said the yield and protein maps in Figure 2 showed some areas of high yield and low protein, “which is the classic agronomic response”.

“But there are also areas of the field where that is not happening. That has to do with nitrogen and water management that is missing. We need to start using these tools to tease this out,” he said.

He said dust was the only significant limiting issue for protein sensors in Australia with operators having to frequently stop to clean them.

“We are a lot drier than many other parts of the world. Keeping the sensing systems clean is something you still need to attend to. It was a really big issue, but the system is far better these days,” he said.

Grain Central: Get our free cropping news straight to your inbox – Click here

HAVE YOUR SAY